NASA Announces Lunar Delivery Challenge Winners

Click here to visit official website

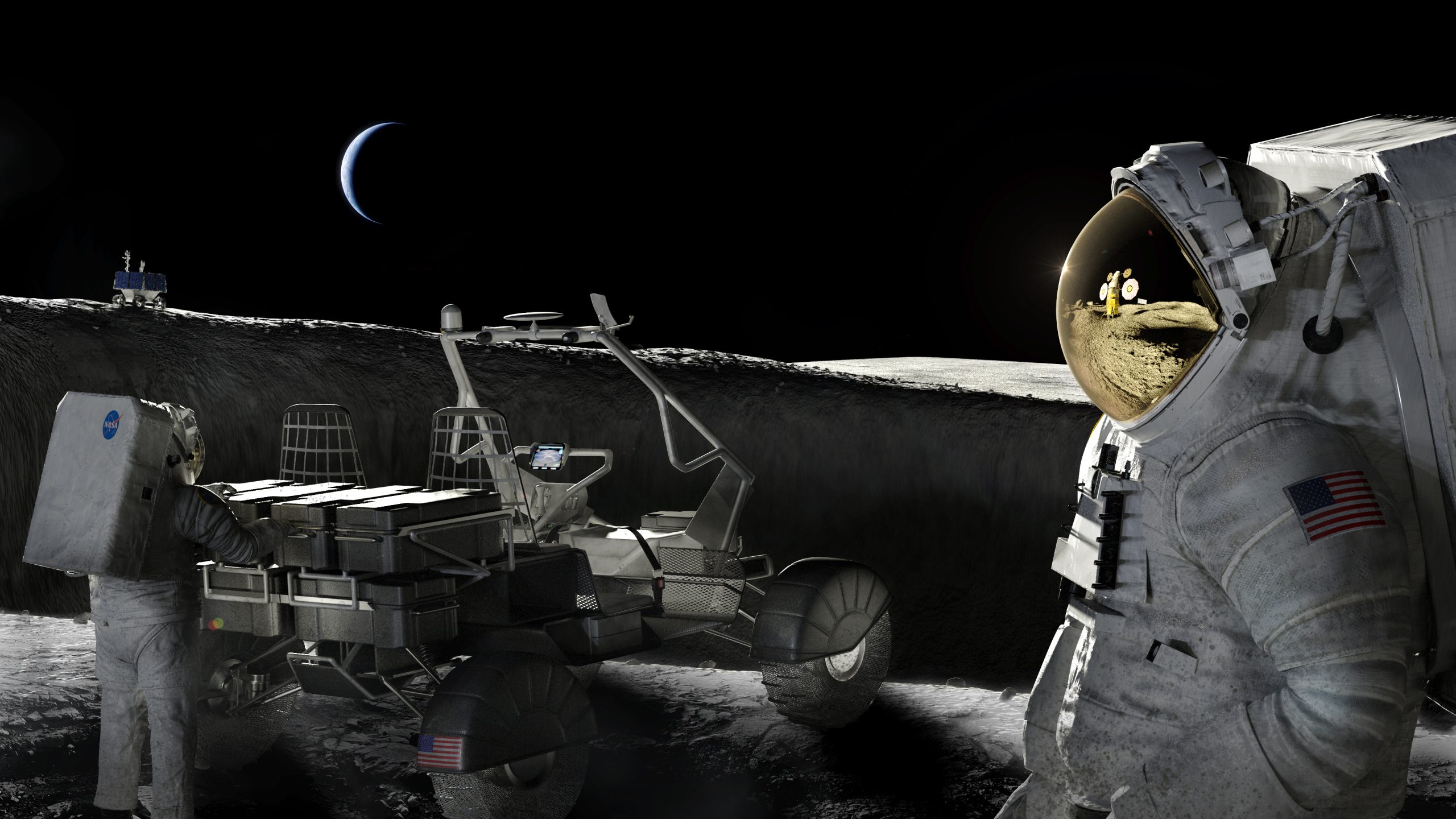

An illustration of astronauts on the Moon.

Credits: NASA

By Danielle Sempsrott

NASA’s Kennedy Space Center

Editor’s note: This feature was updated on March 19, 2021, to include the names of all finalists.

With the Artemis program,NASA will send the first woman and next man to the surface of the Moon, construct a lunar orbiting outpost, and establish a sustainable presence. This will require deliveries of supplies and equipment to the lunar surface, but how to unload the cargo once it arrives is an open question. NASA created the Lunar Delivery Challenge to seek ideas from the public for practical and cost-effective solutions to unload payloads onto the surface of the Moon.

“Seeing some of these new concepts is actually pretty eye-opening,” said Paul Kessler, an aerospace engineer at NASA’s Langley Research Center in Hampton, Virginia, and one of the judges for the challenge. “It’s brought to light some ideas that we had not considered before.”

The challenge received 224 entries before the submission period closed Jan. 19, 2021. The ideas came from various types of space enthusiasts who share a passion for human space exploration, and participants varied from student teams, to individuals from the private sector, to parent-child duos.

NASA awarded $25,000 in total prizes to six teams, including one first place winner with a prize of $10,000; two second place winners with prizes of $4,500 each; and three third place winners with prizes of $2,000 each.

First Place Winners

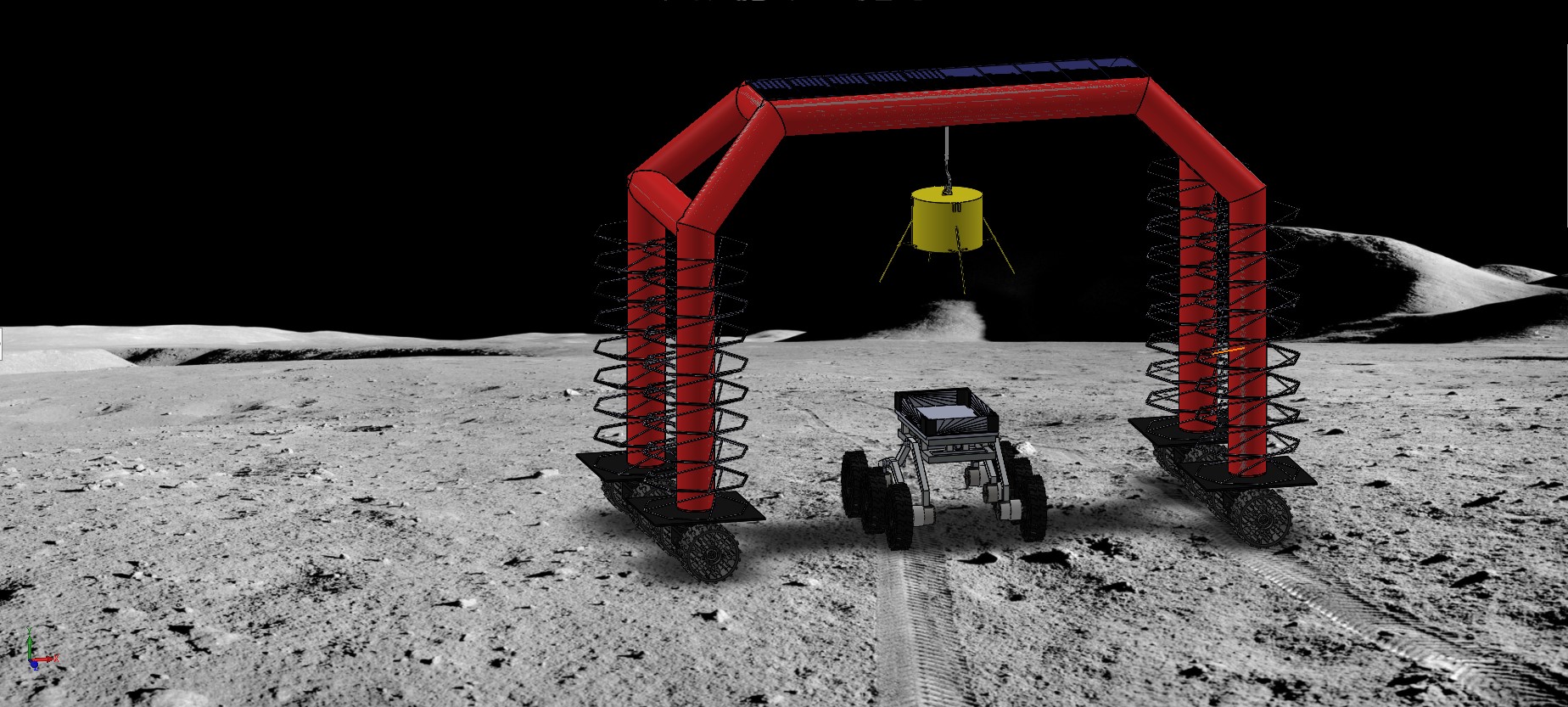

Lightweight Inflatable Delivery System (LIDS) by Lauren Fell

LIDS is an innovative, inflatable gantry with a novel rotatable crane, which makes the system compact, lightweight, and highly versatile. This cost-effective delivery system primarily consists of inflatable components, conserving weight and volume, which offers efficient loading capability.

Other noteworthy features include an autonomous attachment capability that allows it to attach to a wide range of lander hatch heights, and a rotatable component that acts as a forklift, combined with a built-in winch that allows for both vertical and horizontal movement of payloads. Lauren Fell is an avid problem solver.

The Lightweight Inflatable Delivery System by Lauren Fell is the first-place winner of NASA’s Lunar Delivery Challenge. LIDS is an innovative, inflatable gantry with a novel rotatable crane, which makes the system compact, lightweight, and highly versatile.

Credits: NASA

She first participated in NASA’s RFID-Enabled Autonomous Logistics Management (REALM) project storyboard challenge in 2017 and was instantly hooked. She won first place in that challenge and has been competing ever since. Fell has a background in psychology and is in the process of completing a Ph.D. on the application of models from quantum physics to the cognitive science of trust. She also teaches decision science as an associate lecturer at the Queensland University of Technology in Brisbane, Australia, and enjoys expanding their repertoire of skills by competing in NASA challenges.

Second Place Winners

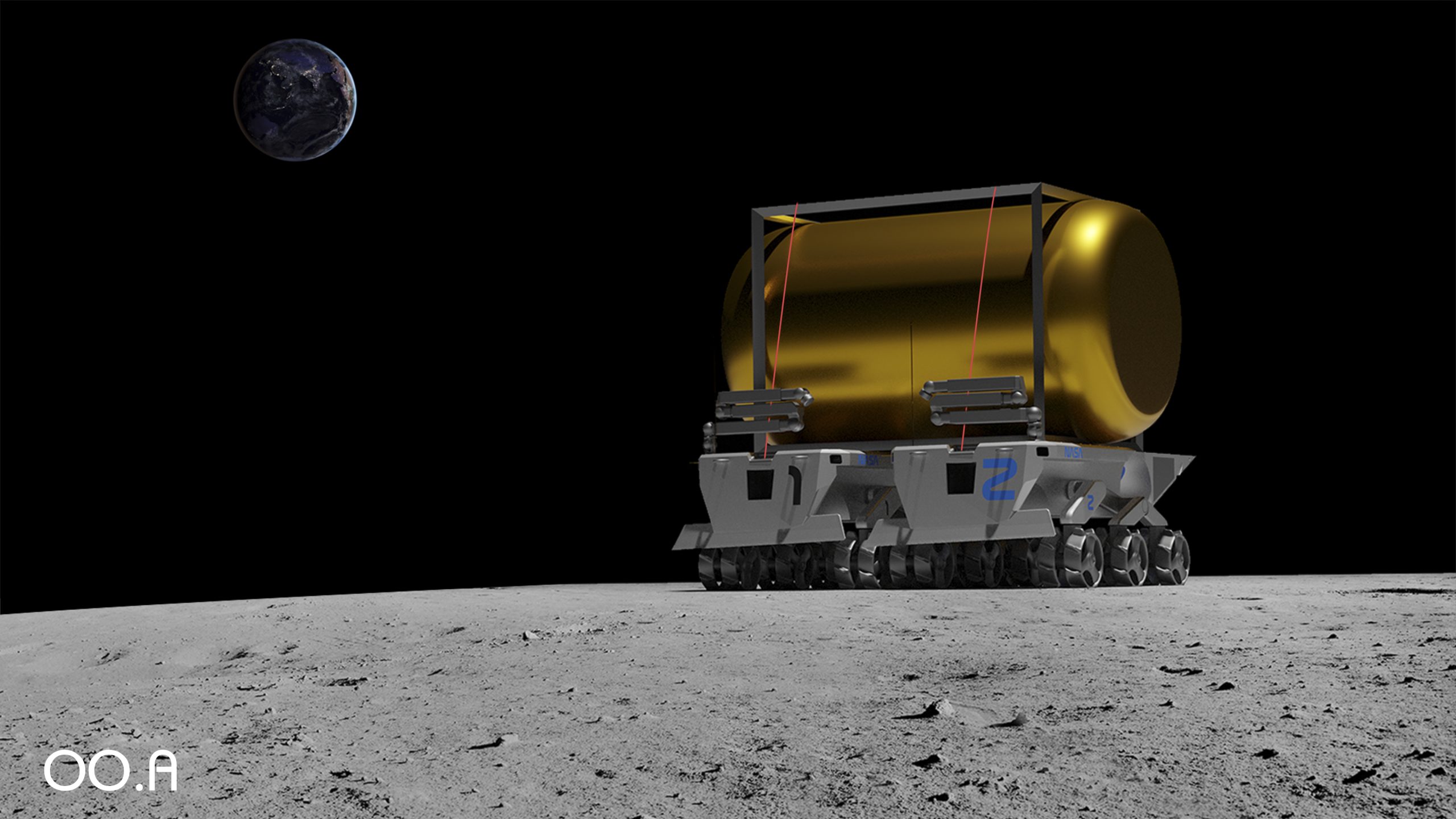

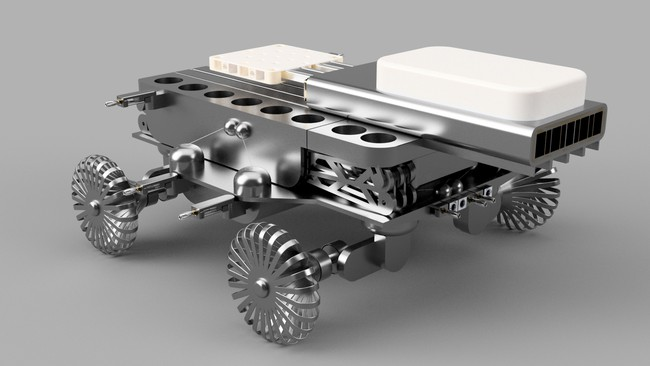

OO.A by Team FRD is one of two second-place winners for NASA’s Lunar Delivery Challenge and is an evolution of the current Mars Rover designs. It can operate autonomously or with other systems to deliver a tough, sustainable and flexible platform for unloading payloads of all sizes.

Credits: NASA

OO.A – mOOngoAt by Team FRD

OO.A is an evolution of current Mars rover designs. The OO.A system can operate autonomously or with other systems to deliver a tough, sustainable, and flexible platform for unloading payloads of all sizes. This multifunctional design proposes simple packaging protocols that allows the lander systems to support various types of tasks, such as mining waste management and other operations across the lunar surface. FRD is a father and son team. The idea was captained and designed by Fenton Robathan and the project was managed by Peter Robathan.

The OO.A system was developed at a design studio based in London that focuses on sustainable and automotive aerospace projects.

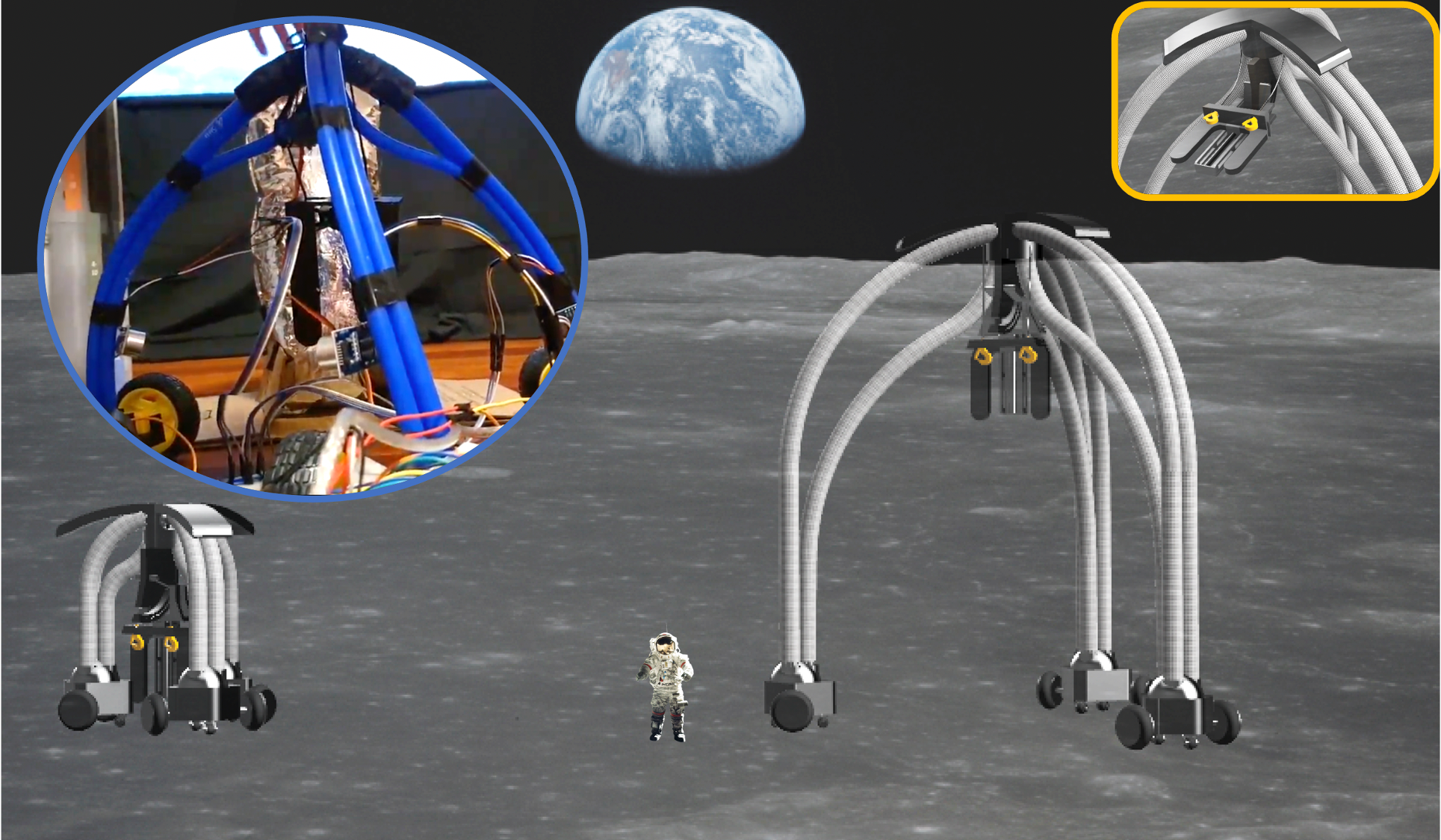

Scalable Payload Delivery System (SPaDeS) by Team SPaDeS

SPaDeS is based on the idea of expanding infrastructure. The design uses a small rover crane for small and medium-sized payloads, and larger payloads are handled with a crane that uses inflatable structures and lunar material. The whole system is designed to provide maximum usability and flexibility in the harsh lunar environment while optimizing structural solutions to keep the mass and volume of the system economical. SPaDeS is a multifaceted team with expertise in mechanical engineering, design, and simulation that has come together to create new and innovative solutions,

The Scalable Payload Delivery System by Team SPaDeS is one of two second-place winners for NASA’s Lunar Delivery Challenge, and it is based on the idea of expanding infrastructure.

Credits: NASA

integrating both old and new technologies. Their solutions are created using open-source software, which demonstrates the overall spirit and vision of the team.

Third Place Winners

The Transporter and Gantry (L-TAG) by Team AA-Star is one of three third-place winners for NASA’s Lunar Delivery Challenge and operates in two phases.

Credits: NASA

Transporter and Gantry (L-TAG) by Team AA-Star

such as hardware needed to build lunar habitats. A deployable shield around the vehicle protects the payload from lunar dust and micro-meteoroid impacts. Team AA-Star consists of an interdisciplinary collaboration with expertise in machine design, electro-mechanical and computer science combined with commercial experience. Surya Narayana Murthy Pappala, the team captain, has a master’s degree in information technology with 12 years of experience and is passionate about problem-solving and optimization. Amareswara Prasad Chunduru has a degree in computer applications and expertise in electro-mechanical engineering and is passionate about non-linear dynamics, machine design, and metaheuristics. Sai Ashish Kumar Karanam has a master’s degree in machine design as well as commercial experience and is passionate about product life cycle management, industrial robotics, and Internet of Things devices.

Modular Lunar Cargo Handling System by Team Sparkletron

The Modular Lunar Cargo Handling System by Team Sparkletron is one of three third-place winners for NASA’s Lunar Delivery Challenge. It is comprised of simple, function-specific modules that interact for complex situation handling, error-tolerance and robustness at scalable costs.

Credits: NASA

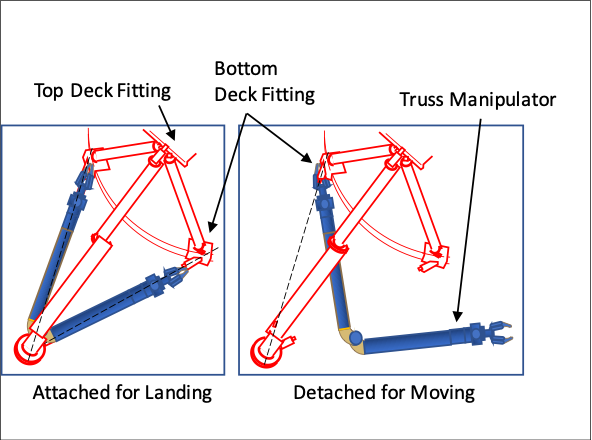

Truss Manipulator by Wendell Chun

The Truss Manipulator by Wendell Chun is one of three third-place winners for NASA’s Lunar Delivery Challenge. It is a multi-purpose solution that starts as a lander leg truss structure that is re-purposed to a manipulator that can take advantage of the lower lunar gravity to move objects around.

Credits: NASA

The Truss Manipulator is a multi-purpose solution that starts as a lander leg truss structure that is repurposed to a manipulator that can take advantage of the lower lunar gravity to move objects around. This “truss-like manipulator” is needed for landing as part of a structural compression element integrated into the lander’s leg assembly, so it does not take up additional payload space. Once landed, the arm will unlatch from the primary lander leg and is free to travel about the lander.Professor Chun is the faculty director of systems engineering at the University of Denver. He is a former aerospace principal investigator for Lockheed Martin Corporation and has worked in robotics since the 1980s, with artificial intelligence systems and .

Challenge judge Tracy Gill said NASA was looking for new and innovative concepts. “We really wanted to reach a wide audience to reinforce or buttress things we already thought were good ideas, and then maybe get some new ideas and look at the obstacles differently,” said Gill, who works in the Mission and Support Control Office at NASA’s Kennedy Space Center in Florida. “We asked people to not worry about executing the design in the lunar conditions; just assume that NASA can help figure that out.”

The challenge focused on autonomous and semi-autonomous solutions for unloading cargo and supplies on the Moon. NASA will consider the ideas and designs brought forward for future planning and development to achieve the agency’s goal of lunar sustainability.

NASA is working with U.S. companies to send payloads to the lunar surface through the agency’s Commercial Lunar Payload Services initiative and the human landing system to carry both astronauts and supplies to the Moon. As a result, offloading solutions need to support a variety of lunar landers, along with a wide range of payloads, a task that Gill said hasn’t been easy.

“We don’t know enough about all the different landers and payloads we might be working with yet, but we do know that we’ll need to offload anything from a small science package to a giant habitat, and that’s why this isn’t such a simple thing to solve,” he said.

Teams at NASA have been brainstorming a number of different solutions for getting cargo off the landers and onto the surface of the Moon. Some of these include a rover that would travel to different landing sites, picking up payloads as they’re delivered, a lightweight robotic crane, or built-in offloading capability for each mission, such as a robotic arm that could drop cargo onto the surface. Regardless of the approach, the offloading systems will have to withstand a harsh environment that has electrostatically charged dust, uneven terrain, large thermal swings, and reduced gravity.

“We know that there’s a real challenge here; Going to the lunar surface and doing human exploration is a challenging endeavor,” Kessler said. “There are a lot of different ideas the general population has based on their own experiences, and that diversity of thought facilitates innovation and allows us go to the leading edge to make sure we have the most successful missions, utilizing some of the greatest and newest technologies out there.”

The NASA Tournament Lab, part of the Prizes, Challenges and Crowdsourcing Program in the Space Technology Mission Directorate, managed the challenge. The program supports the use of public competitions and crowdsourcing as tools to advance NASA research and development and other mission needs. You can learn more about the winning teams and their solutions at the upcoming HeroX winners webinar. Find more opportunities to participate in your space program via NASA prizes and challenges: Professor Chun specializes in multi-disciplinary engineering design to address complex problems.robotic manipulation systems, including self-driving vehicles

Finalists of the challenge were

- Finalists of the challenge were:

- Lunar-MULE (Mobile Unmanned Loading Elevator) Rogelio Morales by Ingenuity Tree

- Oooo The Claw by Ooooo The CLAW Team

- Project Bowstring: A Slide to the Surface by Amelia Rolf

- Smart FOX by Santiago Forcada Pardo

- Tritron Lunar Unloading and Positioning System by Jeff Morse